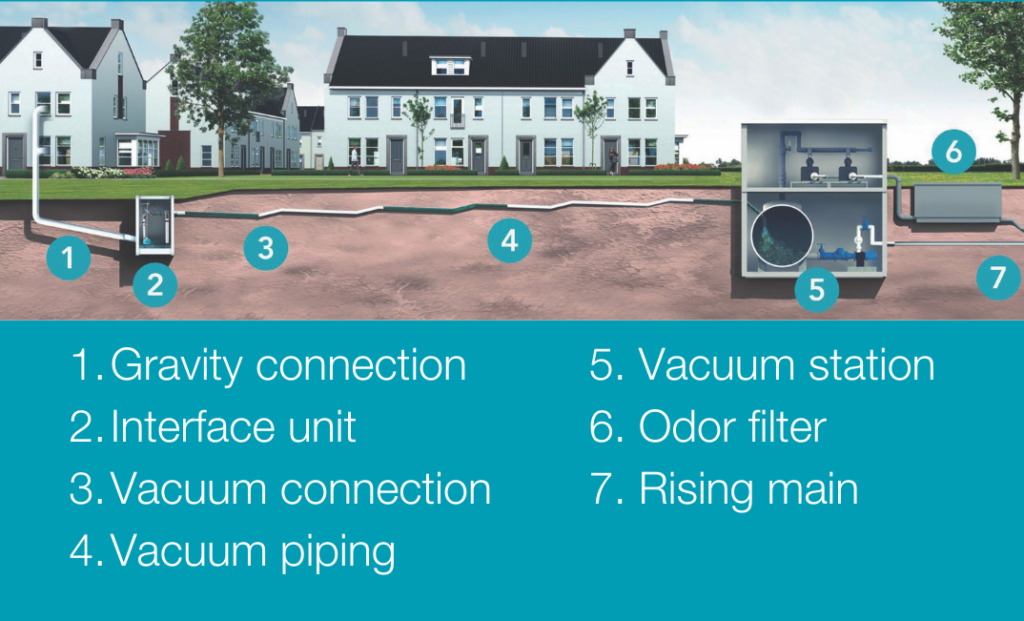

How does a vacuum sewer system work?

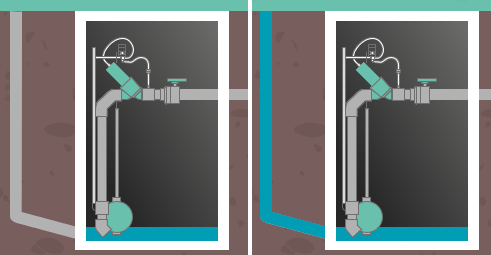

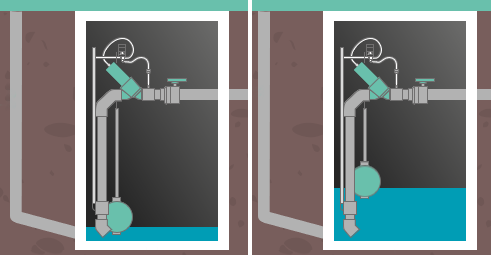

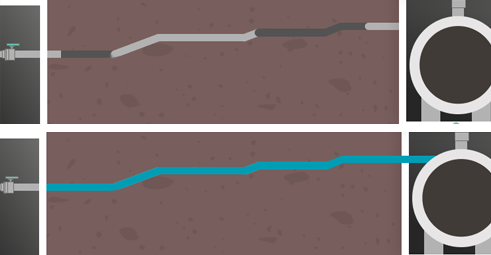

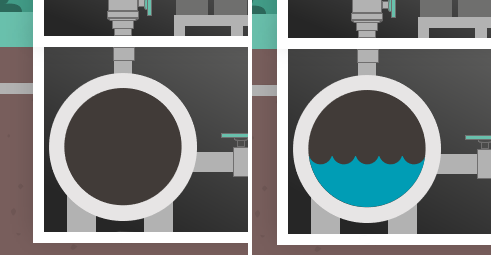

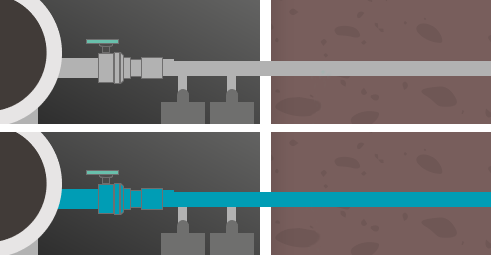

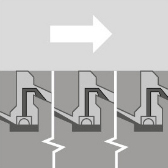

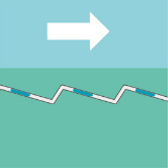

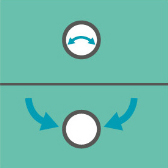

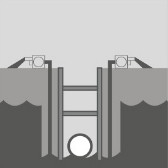

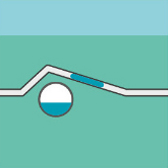

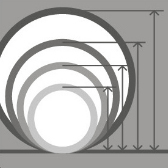

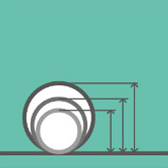

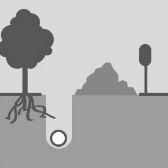

Compared to conventional sewerage systems that make use of gravity, a vacuum sewer system uses a vacuum to transport wastewater. Sewage flows from a building by gravity into a so called wastewater collection chamber with interface unit. After a certain level is reached, a vacuum valve opens and transports the sewage in combination with air into the vacuum network towards a centrally located vacuum station. Here all the sewage is being collected to eventually ben pumped to a nearby discharge point or treatment plant.This technology makes the vacuum sewer system an improved and more cost-effective alternative than conventional sewerage systems. A vacuum sewer system consists of: a collection chamber with interface unit where the sewage is collected, vacuum pipe network through which sewage and air is being transported, a vacuum station where all the sewage is collected with vacuum pumps, vacuum tank, discharge pumps, control panel and odor filter. After the sewage is collected in the station, the sewage will be transported to a nearby discharge point or sewage treatment plant. Gravity flows the sewage into a collection chamber, where it will be stored for a short time. When the level of sewage inside the collection chamber rises, a starter valve activates the vacuum piston valve, which drains the sewage into the vacuum network. Multiple properties can be connected to one collection chamber. Applications of the vacuum sewer system include: recreational areas, summerhouses, marinas, house boat projects, new residential developments, villages, industrial/governmental projects, canal estates, islands and renovation projects.